Alloy steel cold work steel din1.2379 AISI D2 Cr12Mo1V1 MOV tool

steel plate

Hot rolled alloy steel cold work steel D2 Steel Bar for tooling and

die

Introduction

With high wear-resisting cold working die steel, SKD11 steel has

the properties of high strength and high wear resistane, replace a

new generation imported common cold working die steel with high

odburability high wear-resisting.

Key words:

DC53, 1.2990, GS-821, ASSAB 88, SLD-MAGIC, AISI D2, W.-Nr. 1.2379

Chemical Composition (%)

| C | Si | Mn | P | S | Cr | Mo | V |

| 1.4-1.6 | 0.30-0.5 | 0.3-0.5 | ≤0.030 | ≤0.030 | 11-13 | 0.7-1.2 | ≤0.80 |

Product Description

| Size of Steel grade 1.2379 mechanical properties |

| Round bar | Diameter(mm) | Length (mm) | |

| Max:120 | Max: 6000 | |

| Plate | Thickness(mm) | Width (mm) | Length (mm) |

| Max:80 | Max:600 | Max:6000 |

| The specification can be customized. |

Recommend heat treatment:

| Quenching | Tempering |

| Heating temperature/ºC | Cooling way | Hardness (HRC) | Tempering temperature

/ºC | Tempering number | Hardness

(HRC) |

| First preheating | Second preheating | Last heating |

| 600-650 | 800-850 | 1020-1040 | Air Cooling | 61-63 | 500-560 | 2 | ≥58 |

D2 SKD11 1.2379 Characteristic

1, the high obdurability is higher than that of 1.2379, and the

wear- resisting property is good.

2, the high obdurability is more than two times than 1.2379,

overcome the weakness of traditional with easy tip or craze, high

temperature resistance tempering stability better than that of

1.2379/D2,in general and precision mold domain can replace

1.2379/D2, its use performance is the same type cold die imported,

Characteristic curve of quenching and temper.

Heat Treatment

1) Forging

Heat the 1.2379 tool steel slowly and uniformly to 700°C then more

rapidly to 900-1040°C. After forging cool down slowly.

2)Annealing

As supplied 1.2379 is in the annealed and machineable condition.

Re-annealing will only be necessary if the steel has been forged or

hardened by the toolmaker. To anneal, heat slowly and uniformly to

900°C. Soak for three to four hours and allow to cool in the

furnace to room temperature. Re-heat to 800-1040°C and again soak

for three to four hours. Allow to cool in the furnace to room

temperature.

3)Stress Relieving

If tools are heavily machined, ground or otherwise subjected to

cold work, the relief of internal strains is advisable before

hardening to minimise the possibility of distortion. Stress

relieving should be done after rough machining. To stress relieve,

heat the 1.2379 steel component to 600-650°C. Soak well and cool in

the furnace or in air. The tools may then be finish machined before

hardening.

4)Hardening

It is preferable to heat the tools in a controlled atmosphere. If

this is not possible, pack hardening is recommended. A reducing

atmosphere is desirable. Pre heat the 1.2379 tool steel component

to 750-800°C. and allow to soak at this temperature. The tool

temperature should then be brought up to 1000-1040°C for air

cooling, or 980°C for oil quenching. Soak thoroughly at the

temperature for thirty minutes per 25mm of ruling section, then

cool or quench accordingly. It is important not to exceed 1020°C

when heating for hardening.

5)Tempering

Double tempering of is recommended. The tempering should be done

with the least possible delay after hardening, preferably when the

tools are still hand warm. Select a suitable tempering temperature,

bearing in mind the service requirements. Heat slowly and

uniformly. When the 1.2379 component has reached the desired

temperature, soak for at least sixty minutes. The second tempering

should be a repetition of the first.

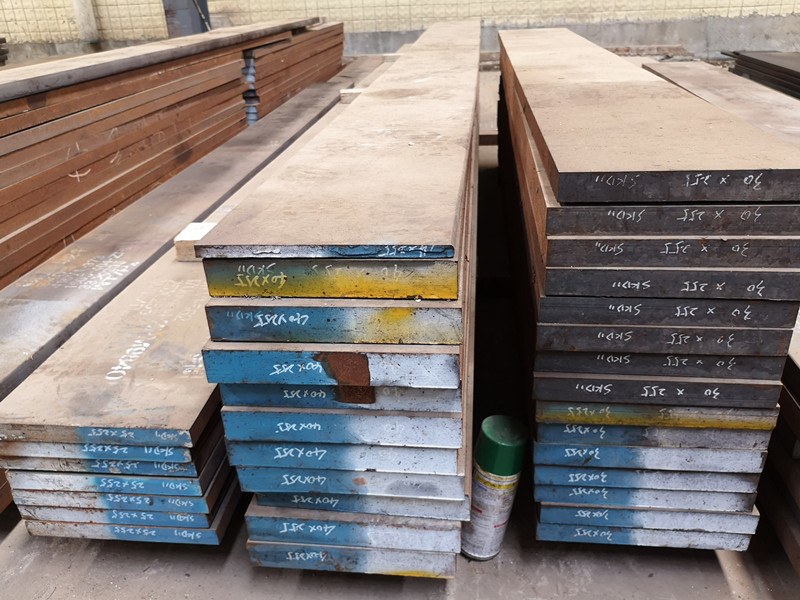

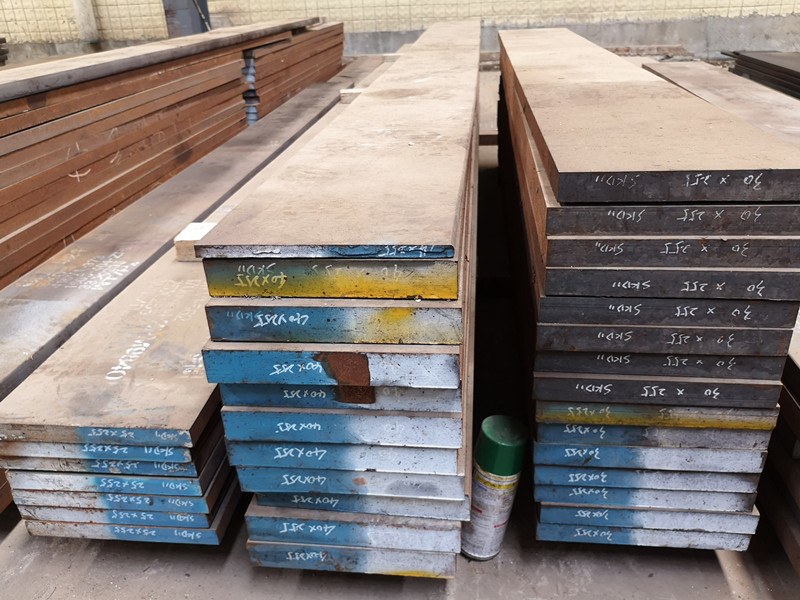

Products show:

Cold Work Alloy Tool Steel for Cutters D2 SKD11 1.2379 round & flat

bar

Features:

A,High wear resistance and toughness.

B,Alternative to oil harding tool steel.

C, Offer a measure of corrosio resistance when polished.

Application

A,Used for making various high precision,long-life cold work mould.

B,Cold heading die, thermosetting resin molding mold, senior gauge,

etc.

C,Deep drawing forming die, cold extrusion dies.

FAQ

Q1: What do you do for the control of the quality?

A1: Before loading into the container, our products will all be

inspected by ultrasonic inspection. Quality Grade conforms to SEP

1921-84 E/e, D/d, C/c as per customer's request.

Q2:: What are your hot-selling products ?

A2: S50C / P20 / D2 / 1.2379 / H13 / 1.2344 / CR12MOV / 4140 /EN19

EN24 EN31, abundant stock for both plates and rounds. Competitive

prices and short lead-time.

Q: Can we visit your company and factory?

A: Yes, warmly welcome! We can book the hotel for you before you

come to China and arrange our driver to our airport to pick you up

when you come.